1. The food homogenizer is designed to be easy to operate and maintain. It can be cleaned with distilled water, pure water and detergent (do not use the pressure switch at this time), or remove the pump head for manual cleaning.

2. The start and stop control buttons of the machine are located on the side of the machine. Homogenizers are easy to operate, can be used for emergency switches, and include thermal and magnetic maintenance of the main motor.

3. The food homogenizer is equipped with a polished all-stainless steel shell, which is detachable for easy inspection and maintenance. Its base stands on four rubber pads.

4. The food homogenizer is fed through its own weight suction and does not need any feeding pump. Only electricity is needed and no other equipment (such as water or compressed air) is needed. According to the requirements of the samples, gaskets of different materials are used. The standard gasket material is special plastics. The plunger seal uses a special PTFE material with lubricating effect.

5. The refinement effect is more intense. This is because the valve core and the valve seat of the working valve are tightly fitted in the initial position, but a slit is forced out by the liquid during operation. In order to meet the high-speed rotation and not generate excessive heat between the rotor and stator of the centrifugal emulsification equipment, there must be a large gap (relative to the homogenization valve). At the same time, since the transmission mechanism of the homogenizer is a positive displacement reciprocating pump, theoretically, the homogenizing pressure can be increased indefinitely. The higher the pressure, the better the refinement effect.

1. Homogenizers are suitable for sample preparation for microbiological analysis of various foods, medicines, and cosmetics. And our company provides the new sterile homogenizer, which is safer when used.

2. Put the substance to be tested into the agitator bag, inject the diluted solution (our company's gravimetric dilutor is suitable for solvent diluent), and then close the glass door. At this time, the crushing disk of the homogenizer will start to slap, and the pressure generated will crush and mix the contents of the bag.

A Tentative Study on the relevance of HACCP certification and infection control in hospital

A Tentative Study on the relevance of HACCP certification and infection control in hospital

Environmental Sanitation Microbiology Testing

Environmental Sanitation Microbiology Testing

Microbiology Test in Food Industry

Microbiology Test in Food Industry

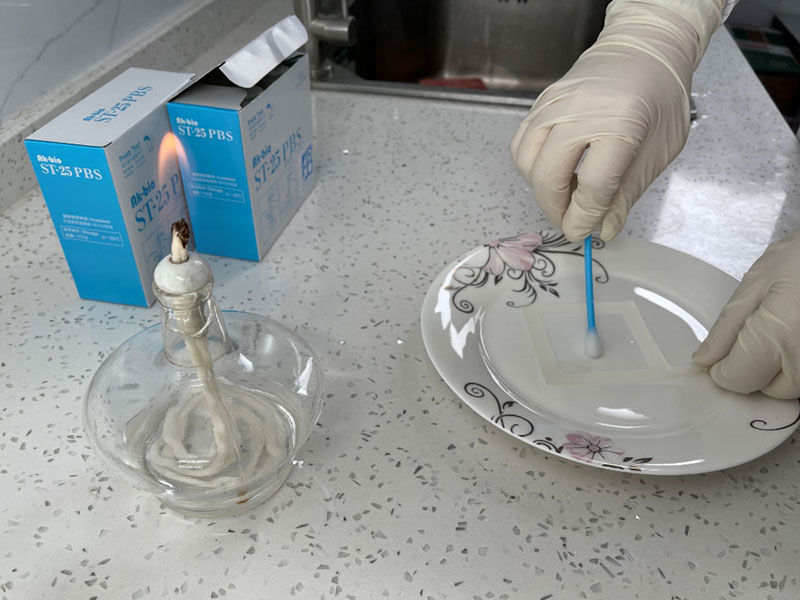

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

Spike Experiment of DNP Culture Media Plate Based on Ice Cream

Spike Experiment of DNP Culture Media Plate Based on Ice Cream