Rigorous testing of sterile sample bags is important to maintain a balance in the production and supply chain. Before filling the product and putting it on the market, the interaction analysis of the liquid and the packaging material can be used to comprehensively test the product to check its taste, vitamin content and freshness, and to find a good packaging solution.

Physical and chemical testing of liquid product formulation, viscosity, pH and carbonation to ensure proper packaging, bottle shape, cap and PET resin. Liquid products are then filled in an aseptic environment and tested in a real environment. At this stage, subjective tests will also be carried out with the help of different sensory analysis methods.

The sterilization factor can penetrate the microbial aseptic bag to kill the bacteria in the packaging bag, and then dissolve the sterilization factor through the pore size of the packaging bag material, so that the items in the bag are stored in a sterile after sterilization. In this state, the bacteria on the outside of the packaging bag are blocked from the outside because it is larger than the pore size of the packaging material. The sterile bags act as a sterile barrier isolation.

With the increase in the application of aseptic bags in the field of beverages and food, the development of the packaging field is also very active, and various composite packaging materials continue to appear. Compared with bottled water, the water outlet principle of water packaging bags is completely different. The bagged water is discharged by atmospheric pressure, which is positive pressure. Bottled water is replaced by air and water, and it is negative pressure water. The drinking water in the water packaging bag, like sterile plastic bags, is fully sealed and does not come into contact with the air, which solves the secondary pollution, while the drinking water in the bottled water is fully open for drinking. The process of drinking from a full bucket of drinking water to a full bucket of air is essentially a process of drinking water being polluted.

Based on the principle of "survive by service and develop by quality", AL focuses on providing professional microbial testing solutions, mainly serving food production enterprises and epidemic prevention stations at all levels. Most of the company's products are sold to Japan, South Korea, Germany, Taiwan, Southeast Asia, Europe and the United States, and have a good reputation.

You may also be interested in these products:

Have any questions?—— We are here to help!

A Tentative Study on the relevance of HACCP certification and infection control in hospital

A Tentative Study on the relevance of HACCP certification and infection control in hospital

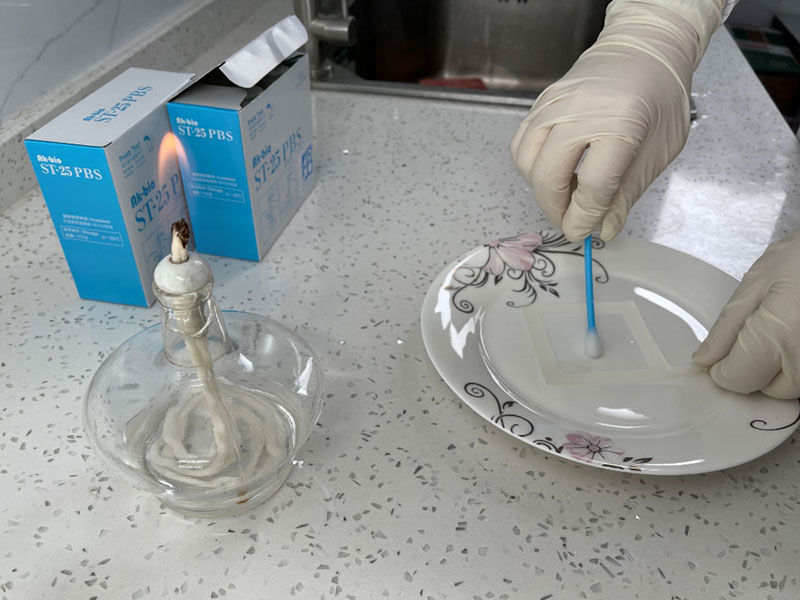

Environmental Sanitation Microbiology Testing

Environmental Sanitation Microbiology Testing

Microbiology Test in Food Industry

Microbiology Test in Food Industry

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

Spike Experiment of DNP Culture Media Plate Based on Ice Cream

Spike Experiment of DNP Culture Media Plate Based on Ice Cream