Aseptic bag fresh packaging is the most popular in the food industry of various countries, and its use is not limited to juice or beverages, but also used to package milk, mineral water and wine. One-third of beverages in the UK have been packaged aseptically. Canadian apple juice has been processed aseptically. Japan has developed a mineral concentrated absorbent paper bag with calcium phosphate as the material, which is used for packaging vegetables and fruits and other foods, so that the vegetables and fruits can get nutrient supply from the mineral concentrate.

The use of aseptic bags is still very important in the food packaging industry. And the sterile bags also belong to food testing lab supplies.

The sterile sample bags absorb ethylene gas and carbon dioxide released from vegetables and fruits, inhibit the decomposition of chlorophyll, and play a role in maintaining freshness. The mall introduced fresh fruit bags made of natural activated clay and polyethylene plastic. The fresh-keeping bag is like a very fine filter sieve. Gas and water vapor pass through the bag to make the fresh-keeping period of fruits and vegetables more than doubled. Moreover, the packaging bag can be reused, is easy to recover, and the price is not higher than that of ordinary plastic bags.

With the development of the economy, people's living standards are constantly improving, and the use of aseptic food sample bags is becoming more and more important to people's lives. The expansion of food bags is becoming more and more diversified, which can satisfy customers of different levels. Food bags such as sterile vacuum bags, convenient plastic bags, and environmentally friendly paper-plastic composite bags are also increasingly appearing on the market.

Aseptic sealed bags play an important role in ensuring the safety of transportation. The packaging is convenient for adding, loading and unloading, stacking, displaying, selling, opening, repacking and reuse.

Use the sterilization factor to penetrate the sterile bag to kill the bacteria inside the packaging bag, and then dissolve the sterilization factor through the aperture of the sterile packaging bag material to ensure non-toxic residue. In this way, the items inside the aseptic bag are kept in a sterile state after being sterilized, and the bacteria on the outside of the packaging bag are isolated from the outside because it is larger than the aperture of the packaging material. The aseptic sealed bag plays a role of aseptic isolation.

A Tentative Study on the relevance of HACCP certification and infection control in hospital

A Tentative Study on the relevance of HACCP certification and infection control in hospital

Environmental Sanitation Microbiology Testing

Environmental Sanitation Microbiology Testing

Microbiology Test in Food Industry

Microbiology Test in Food Industry

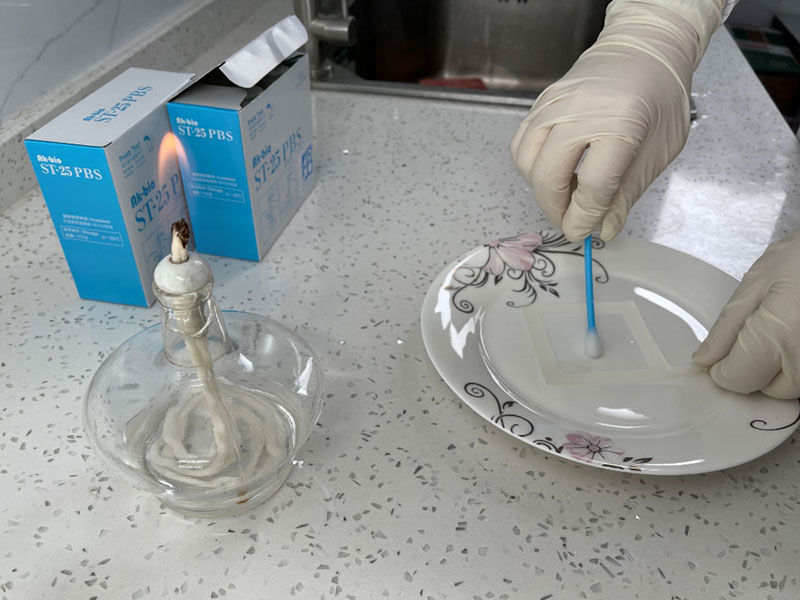

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

The Applicability of High-quality Ready-to-use Swab Sampler for Tableware Sampling and Public Places Supplies and Utensils Microorganisms

Spike Experiment of DNP Culture Media Plate Based on Ice Cream

Spike Experiment of DNP Culture Media Plate Based on Ice Cream